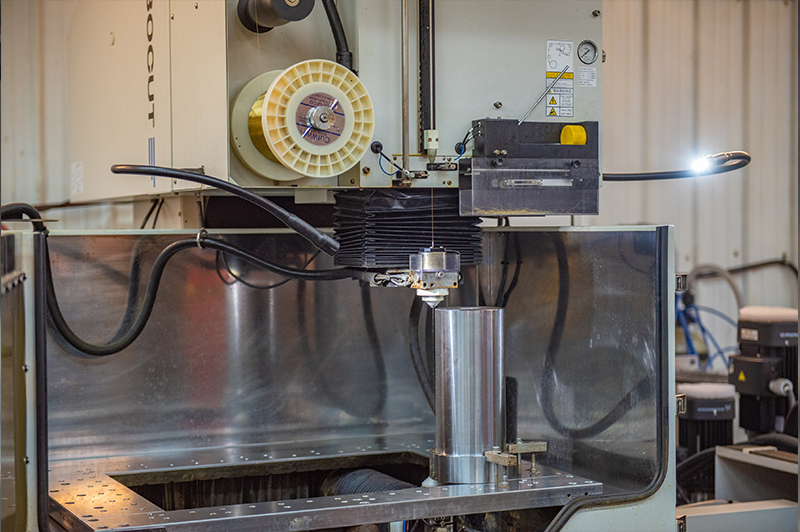

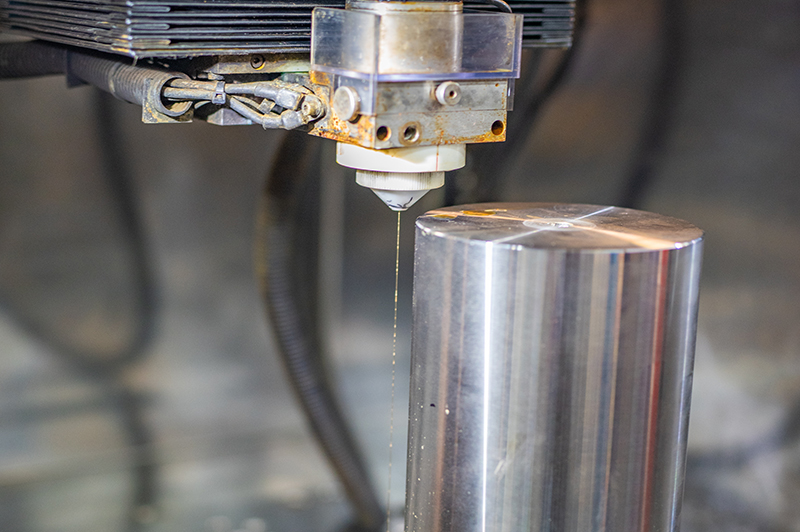

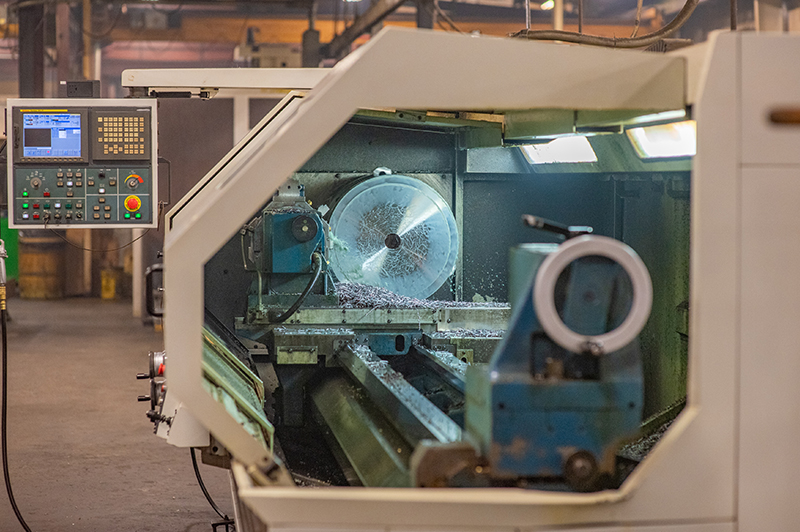

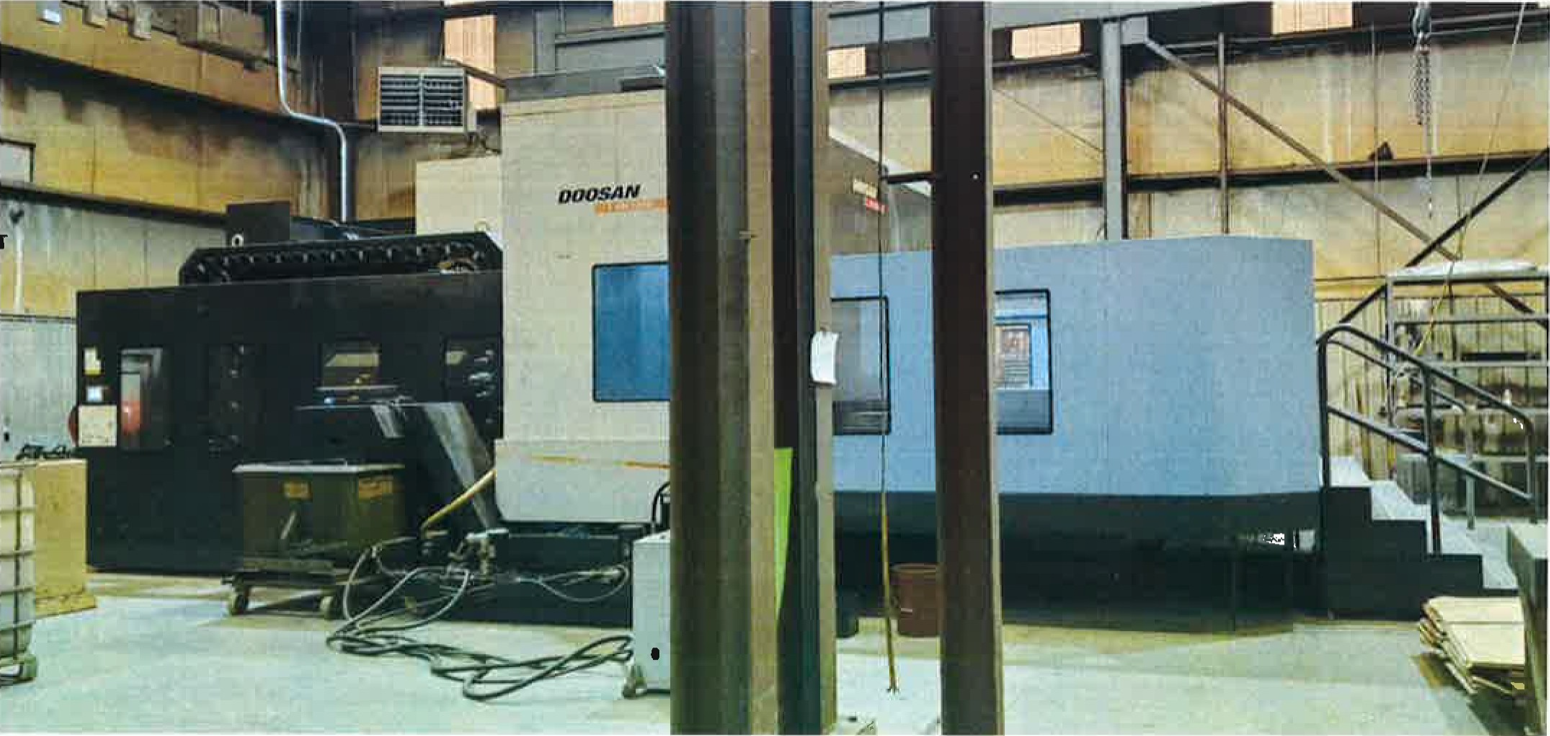

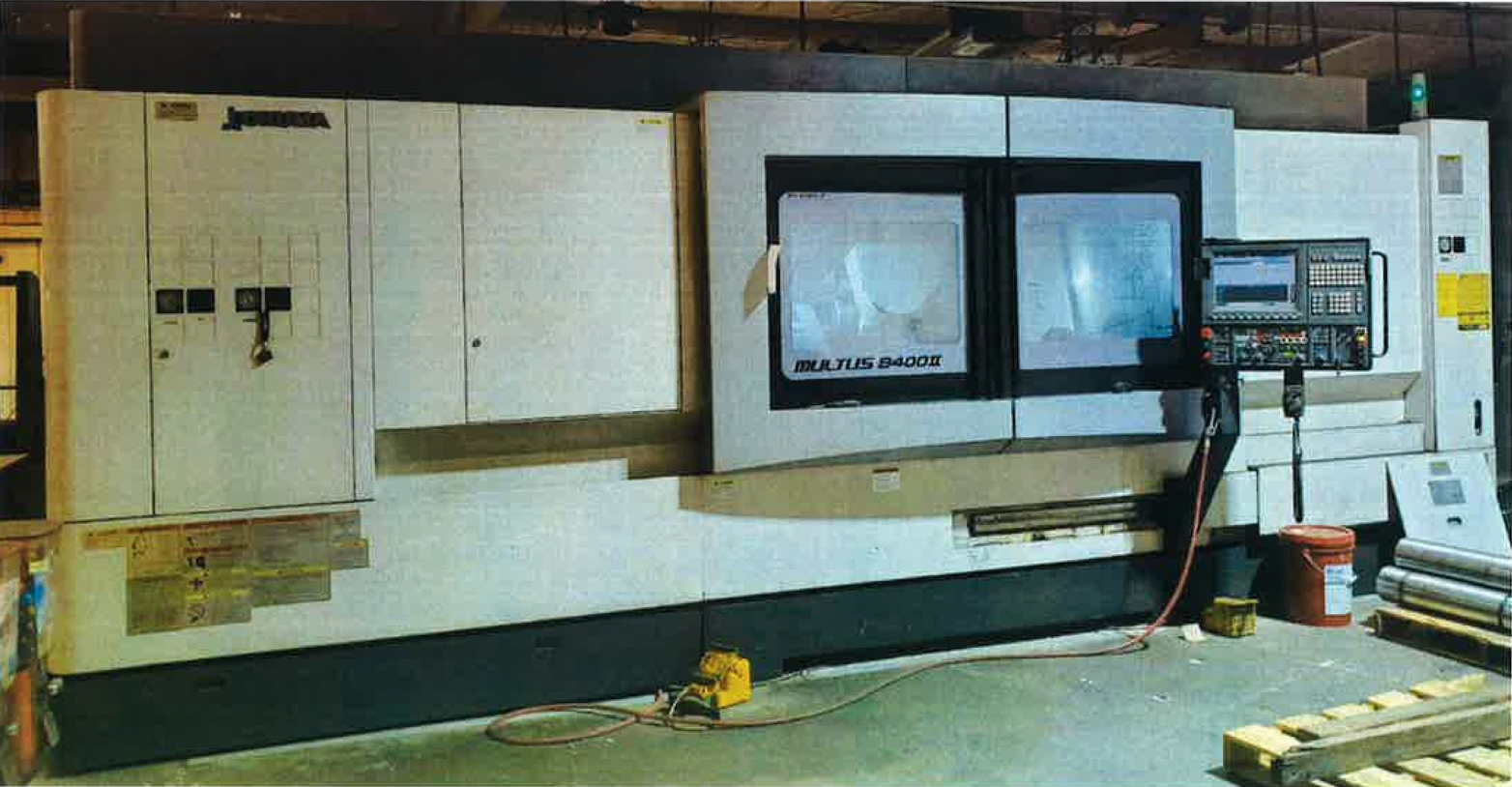

Your main focus is on keeping production or construction moving forward. And, since that’s your focus, it’s ours too. We have a variety of machining capabilities to get the job done, whether it’s on a 1lb piece or a 25 ton assembly, we have you covered.

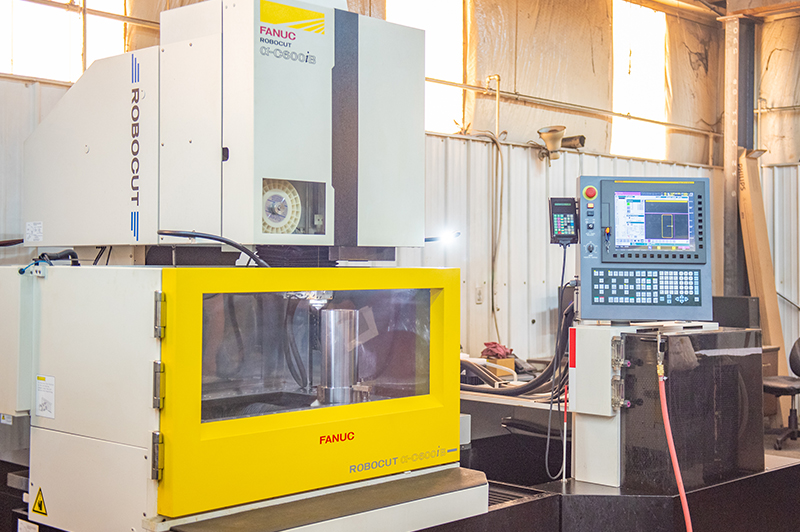

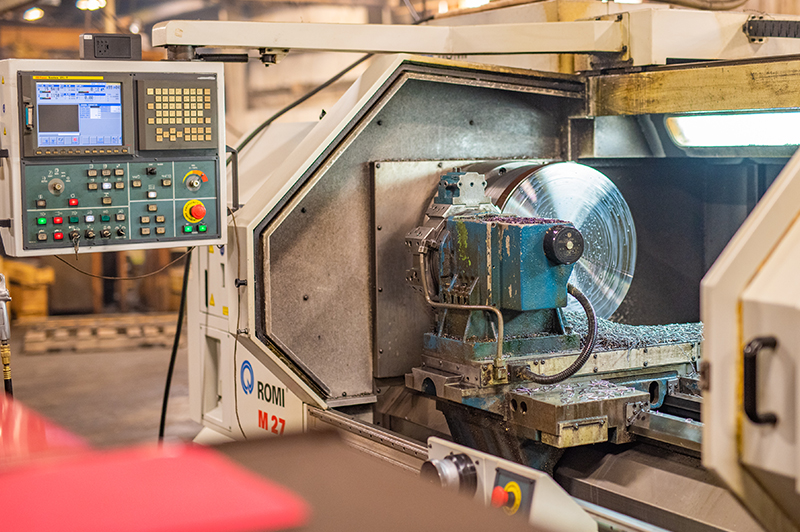

Our specialty is in large machine repair and large part CNC machining. We understand the stress equipment failure can cause, so we’ve equipped ourselves to be your Machine ER with pickup and delivery services. You can’t afford a stalled project, so we partner with you to ensure you’re able to get back on schedule quickly.

For a full range of our capabilities, let’s have a conversation about your project. Email us at kme@kymachine.com.